Description

Applications:

Manufacturing:

- Automotive & electronics

- Use on LSE painted metals and plastics post powder coating and oven-stoving.

- Suited to glass, acrylic or polycarbonate

Signage:

- Virtually impervious to UV, temperature, ageing or chemicals.

- Ideal for durable, long-lasting signs in the harshest environments.

Features & benefits

- Specially formulated for low surface energy bonding

- Incredibly high bond strength delivers durability and longevity

- Special low surface energy adhesive formulation means you may not need to abrade or prime

- Withstands:

- Extremes of temperature

- High forces applied to the bond

- Water

- Most solvents and chemicals

- Differential expansion and contraction

- Interior or exterior performance

- Easy release siliconised filmic liner improves assembly times

- High tack and good initial handling strength for improved production speeds and aesthetics

- Can replace spot welds or mechanical fasteners

- Ultra-high sheer and high cohesion – ensuring the tape (and bond) remain strong under stress

- Resists vibration

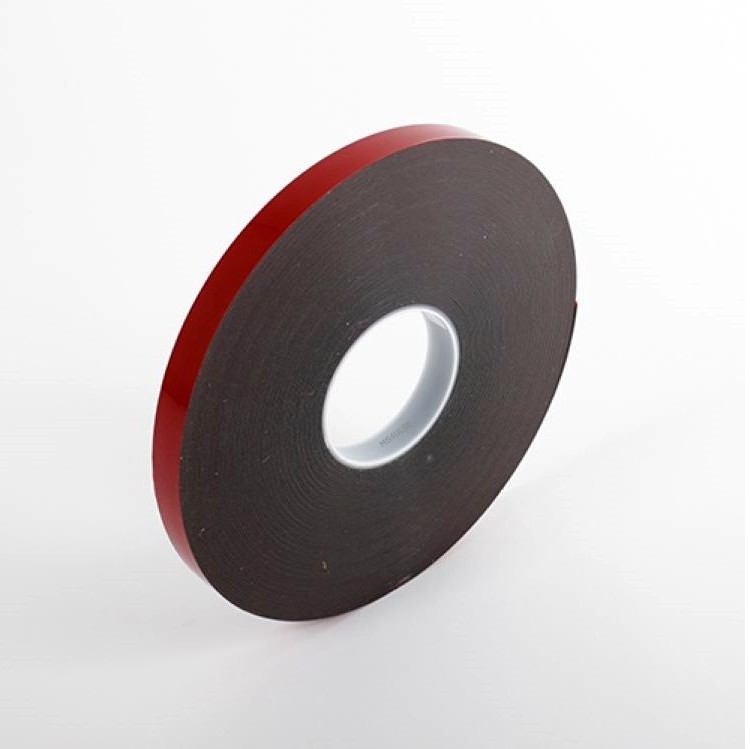

- 1.1mm thickness Grey/Black tape with red filmic liner

Technical information

| Colour | Black |

| Thickness | 1.10mm |

| Carrier | Acrylic foam |

| Liner | Silicone coated paper/PE film |

| 90° Peel Adhesion according to AFERA 5001 | Steel 35N/25mm – PVC 23N/25mm – Aluminium 31N/25mm |

| Static Shear Strength (to stainless steel) | 1500g @ 23°c : 500g @ 93°c |

| Dynamic Shear (@200mm/min) | 73N/cm2 (after 2 hours) : 84N/cm2 (after 24 hours) : |

| Operating Temperatures | Short term (mins/hrs) 150°c : Long term (days+) 120°c |

| Application temperature | Minimum 15°c (ideally between 21°c and 40°c) |

| Temperature resistance according to ISTM D3654 method | From -40°c to +150°c (long term) 260°c+ (short term) Area of 6.25² with 1kg load @ 150°c for 10,000 minutes |

| Solvent Resistance | High |

| UV Resistance | Excellent |

| Standard roll option dimensions | 12, 19 & 25mm widths x 33m rolls |

How to apply MS4110LSE-BLK acrylic tape

The surfaces to be bonded should be dry, dust and grease free and thoroughly clean. Avoid touching the exposed adhesive surface of the tape as this impairs the performance.

The adhesive used on these tapes are pressure sensitive, so always ensure sufficient pressure is applied to the tape evenly over the whole surface to ensure the best bonding results.

- Abrade (roughen) the surface where possible to provide a ‘key’ to which the tape can bond, increasing the bond strength by as much as 35%

- Clean with Surface Cleaner

- Prime the surface using Surface Primer

- Using the correct primer can increase final bond strength by up to 50%. Remove the blue silicon liner.

- Align the parts to be bonded.

- With firm pressure, apply MS4110LSE-BLK to one of the surfaces to be bonded.

- Using a MS4U -roller will allow the double-sided acrylic tape to wet out and reach ultimate bond strength more quickly.

- Apply firm pressure to the bond with the MS4U roller.

- Ultimate bond strength will be achieved in 72 hours